Ever stared at a four‑channel amplifier and thought, “There’s got to be a way to get more power out of this without buying another box?” You’re not alone – we’ve heard that exact sigh from car‑audio hobbyists countless times.

The trick? Bridge two channels together and you instantly double the voltage swing, giving your subwoofer that extra punch you crave.

But before you start snapping wires, there are a few things to keep straight – otherwise you might end up frying the amp or getting a weak, distorted roar.

First, check the amp’s manual for its bridging capabilities. Some models, like the Arc Audio MOTO 720, let you bridge at 2 Ω per channel, while others only support 4 Ω bridges. Knowing the impedance you can safely run is the foundation of a clean install.

Next, decide which pair of channels you want to bridge. Typically you’ll join the left‑front with left‑rear for a mono‑bass channel, or the right pair if your sub sits on the passenger side. It’s a good idea to label the wires now – you’ll thank yourself when you’re tightening the final nuts.

Now for the wiring. Grab a decent gauge speaker wire – 12‑awg works for most street‑legal builds – and run it from the amp’s bridge pins to the subwoofer’s terminals. Make sure you keep polarity straight: positive on the amp to positive on the speaker, negative to negative. A quick sanity check is to measure the resistance between the bridged terminals; you should see roughly half the single‑channel rating.

Finally, give the amp a quick power‑on test before you bolt everything down. Listen for a clean, deep thump – no clicking, no buzzing. If anything sounds off, double‑check your bridges and polarity, then tighten the bolts.

So, does bridging a four‑channel amp sound intimidating? Not really – it’s just a matter of respecting the amp’s specs, keeping your wiring tidy, and testing before you lock it in. In the next sections we’ll walk you through the exact steps for popular models, plus a quick checklist to keep you on track.

TL;DR

Wondering how to bridge a 4 channel amp without guesswork?

In just a few minutes you’ll learn the exact wiring steps, polarity checks, power‑on test, verify the amp’s manual and run proper 12‑awg wire so your sub roars cleanly and safely, leaving you confident to quickly finish the install today.

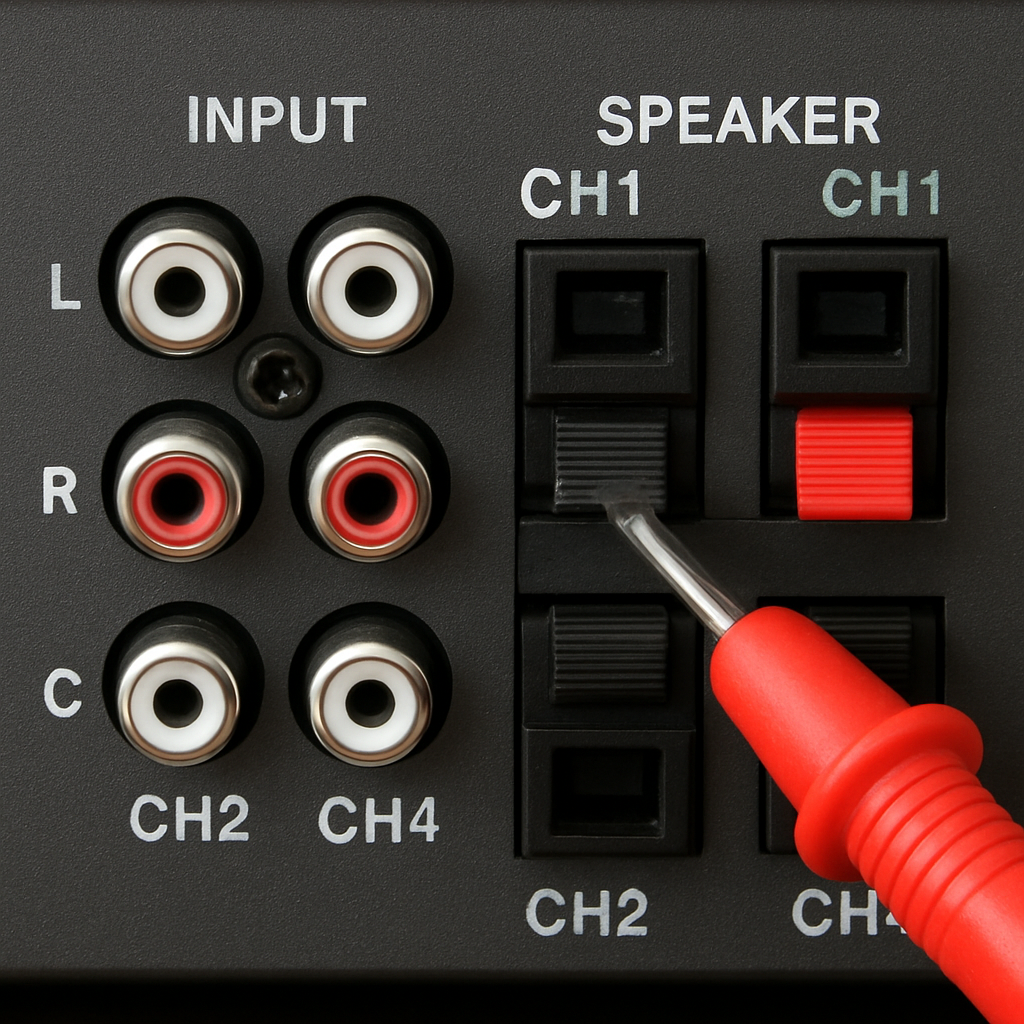

Step 1: Identify Your Amp’s Input/Output Configuration

First thing’s first – you need to know exactly what pins your amp is giving you to work with. It sounds simple, but I’ve seen more than a few installers stare at a four‑channel board and wonder which pair is the “bridge‑ready” combo. Grab the manual, flip to the wiring diagram, and locate the input terminals (usually labelled R‑L, R‑R, etc.) and the output speaker posts. If the amp is a model like the Arc Audio MOTO 720, the spec sheet will actually call out which channels can be bridged and at what impedance.

Once you’ve got that sheet open, trace the signal flow: RCA inputs on the front, speaker outputs on the back, and any dedicated bridge pins. Some amps label the bridge pins as “B+” and “B‑”; others just expect you to join the positive of one channel to the negative of its partner. Write down the exact pair you plan to bridge – left front with left rear, or right front with right rear – and note the polarity markings. This little checklist saves you from a night of guessing and a potential fried amp.

Now, before you start cutting wires, double‑check the power‑rating. Bridging effectively halves the load impedance, so a 4 Ω per channel amp will see a 2 Ω load when bridged. If your amp’s specs say it’s stable to 2 Ω only when bridged, you’re good to go; otherwise you might need a higher‑power amp or a different wiring scheme. This is the moment where many hobbyists get tripped up – they assume any four‑channel amp can be bridged, but the internal circuitry often tells a different story.

Here’s a quick sanity test: with the amp off, use a multimeter to measure resistance between the two channels you intend to bridge. You should see roughly half the resistance of a single channel. If the reading is way off, you’ve probably picked the wrong pair or the amp isn’t bridge‑ready.

And don’t forget the ground. A solid chassis ground reduces hum and protects your gear. Make sure the amp’s ground strap is firmly attached to the vehicle’s metal chassis – a loose bolt can turn a clean roar into a noisy mess.

For those who like to keep everything tidy, consider using a wiring harness that groups the bridge pair together. It makes labeling a breeze and helps when you need to route the speaker wire to the subwoofer. If you’re pulling 12‑awg speaker wire (our go‑to gauge for most street builds), keep the run as short as possible to minimise resistance.

Feeling a little overwhelmed? Imagine you’re setting up a home theater: you wouldn’t connect the left and right speakers without checking the receiver’s manual, right? The same principle applies here – the amp is your receiver, and the subwoofer is the bass‑heavy speaker you’re about to unleash.

One handy resource for picking the right amp in the first place is our top 4‑channel amplifiers guide. It walks you through the specs you need to match with your sub, so you can avoid a mismatch before you even start wiring.

Now that you know what you’re working with, let’s talk about the actual bridge pins. Most modern amps have a dedicated “bridge” switch or a pair of pins you simply tie together with a short piece of wire. If there’s a switch, set it to “bridge” and you’re done. If it’s pins, connect the positive of one channel to the negative of its partner – think of it like creating a seesaw where the two halves push against each other, doubling the voltage swing.

Notice how the video walks through the pin‑pairing on a popular 4‑channel amp? Pause it, grab your multimeter, and verify those pins match your notes.

Once you’ve confirmed the correct pins and polarity, you can move on to actually splicing the speaker wires. But before you do, think about the bigger picture – many car‑audio enthusiasts also integrate their vehicle’s sound system with a smart‑home setup. If you ever want to control your subwoofer from a phone app, a smart home automation solution can bridge the gap between your car and your living room, letting you tweak bass levels from anywhere.

And while you’re in the garage, you might want to add a few extra accessories – a high‑quality Bluetooth receiver, a signal splitter, or a custom‑mounting bracket. Sites like ManCave curate exactly the kind of premium gadgets that make a clean install look as good as it sounds.

Finally, give yourself a quick visual checklist before you tighten any nuts:

- Manual open, bridge‑ready channels identified

- Polarity markings noted and matched

- Multimeter resistance check completed

- Ground strap secure

- Wire gauge chosen (12‑awg recommended)

Cross those off, and you’re ready to move on to the actual wiring step. Trust the process, and you’ll avoid the dreaded “no‑sound” surprise when you power up.

Step 2: Choose the Right Bridgeable Channels

Now that you’ve mapped every pin, the next puzzle piece is deciding which pair of channels you actually want to bridge. It sounds simple, but the choice can mean the difference between a tight, punchy thump and a mushy, half‑hearted growl.

First, ask yourself: which speaker in your car is going to carry the bass load? Most of us end up with a sub that lives under the rear seat or tucked in the trunk. If that’s the case, you’ll probably want to bridge the two rear‑channel outputs – FL and RL on the left side, or FR and RR on the right side – because the wiring run stays short and you avoid feeding the front speakers with a massive low‑end signal.

Match the channel pair to your sub’s placement

Picture this: you’re in a hatchback, the sub is snug behind the rear seat, and you’ve got a 4‑channel amp that labels its outputs as FL, FR, RL, RR. Bridging the rear pair (RL + RR) keeps the high‑current path local, reduces voltage drop, and makes heat‑management easier.

On the other hand, if you’re installing a sub in the front footwell of a sedan, you might bridge the front pair instead. The key is to keep the bridge‑channel wires as direct as possible to the sub’s terminals.

Check the amp’s bridge‑ready pins

Not every 4‑channel amp lets you bridge any two channels at will. Some models, like the LEA CONNECT SERIES CS354, explicitly label “Bridge A” and “Bridge B” pins that correspond to specific channel pairs. Those pins are engineered to share the same ground reference, which is crucial for safe bridging. LEA’s CS354 documentation shows exactly which pins you can tie together without frying the unit.

If your amp’s manual doesn’t call out bridge pins, look for a wiring diagram that groups channels into “bridge‑able pairs.” That diagram will usually indicate whether you can bridge left‑front with left‑rear, or right‑front with right‑rear. When in doubt, a quick continuity test with a multimeter will confirm the channels are isolated from each other.

Mind the impedance rating

Every amp has a sweet spot for bridged impedance – usually 2 Ω or 4 Ω. If you try to bridge a pair that the amp only supports at 4 Ω while your sub is 2 Ω, you’ll end up overheating the amp in a matter of minutes.

So, once you’ve picked the channel pair, double‑check the spec sheet: does the amp say “2 Ω bridge” or “4 Ω bridge”? Match that to your sub’s rated impedance and you’ve eliminated a common failure mode before it even starts.

Practical tip: label before you cut

Grab a piece of masking tape, write “RL‑RR Bridge” on it, and stick it on the speaker wire bundle. It’s a tiny step that saves you from swapping wires later when you’re already under the dash, trying to remember which pair you chose.

And if you’re the kind of installer who loves a visual aid, sketch a quick diagram on a scrap of paper – two circles for the amp outputs, a line connecting the pair you’re bridging, and a note of the impedance. That little sketch becomes your cheat‑sheet when you’re tightening the final nuts.

Does this feel overwhelming? Not really. It’s just a series of tiny decisions that, when taken together, give you a solid foundation for a clean bridge.

After the video, take a moment to verify the bridge pins on your own amp. If the pins line up with the diagram you just saw, you’re ready to move on to the actual wiring – the next step will walk you through connecting those pins to your sub’s terminals.

Step 3: Connect the Speakers and Set Up the Bridge

Why the bridge matters

At this point you’ve already mapped the pins and picked the pair you’ll bridge. The next question is: how do you actually get that pair to talk to your sub without creating a short or a phase mess?

Think of the bridge as a tiny bridge‑builder in your car’s audio world. It takes the positive output of one channel and the negative of the other, then lets the sub see the full voltage swing. Get it wrong and you’ll hear a thin, tinny thump or, worse, fry the amp.

Step‑by‑step: wiring the bridge

1. Gather the right wire. For most street builds 12‑AWG speaker cable is plenty, but if you’re pushing 400 W+ per bridged pair, step up to 10‑AWG. The thicker copper keeps resistance low, which means less heat and tighter bass.

2. Strip and prep. Strip about ½ inch of insulation from each end. Twist the strands lightly – you’ll want a solid connection when you crimp or solder.

3. Identify the bridge pins. Look back at the diagram you sketched earlier. Usually the amp marks a “+ Bridged” and a “‑ Bridged” terminal. If the amp uses standard speaker‑level outputs, you’ll join the positive of the first channel to the negative of the second.

Here’s a quick visual you can imagine: a ‘+’ on the left‑front output and a ‘‑’ on the left‑rear output become the two leads you run to the sub.

4. Connect the wire. Clip one end of the wire to the positive bridge pin, the other end to the negative bridge pin. Tighten the terminal screws until you can’t wiggle the conductor. A loose screw is a silent killer – you’ll get intermittent clicks that sound like a bad connection.

5. Run the wire to the sub. Route the cable along the factory wire harness where possible. Use zip‑ties every 12‑inches to keep it tidy and to prevent rattles. If you have to cut through the dash, protect the wire with a sleeved conduit.

6. Attach to the sub’s terminals. Most subwoofers have clearly marked + and – posts. Match the polarity exactly: the ‘+’ from the bridge goes to the sub’s ‘+’, the ‘‑’ to the sub’s ‘‑’. If you flip them, the bass will sound hollow, as if it’s pushing the car forward instead of pulling it down.

7. Double‑check continuity. Before you power up, set your multimeter to ohms and measure between the two bridge leads. You should see roughly half the resistance of a single channel – that’s the tell‑tale sign the bridge is wired correctly.

Real‑world example: the ARC Audio MOTO 720

One of our customers installed an ARC Audio MOTO 720 in a 2019 Golf hatchback. They bridged the rear‑left (RL) and rear‑right (RR) channels to drive a 12‑inch 400 W sub. Using 12‑AWG wire, they followed the steps above and measured 2 Ω across the bridge – exactly what the amp’s spec sheet calls for. After a quick power‑on test they heard a clean, punchy thump with no distortion. The key was keeping the wire run short (about 18 inches) and securing it with zip‑ties to avoid any movement when the car hit a pothole.

Tips from the pros

- Use a colour‑coded wire (red for +, black for –) – it saves you from swapping polarity later.

- If your amp has a “bridge enable” switch, flip it on before you power up. Some models won’t deliver full output until the switch is engaged.

- Consider adding a small inline fuse (2 A for 12‑AWG, 3 A for 10‑AWG) near the amp. It protects both the amp and the sub if a short ever occurs.

- When in doubt, watch a quick visual guide – for instance, this YouTube walkthrough walks you through the exact pin‑to‑pin connection for a typical 4‑channel amp bridging tutorial.

Final sanity check

Turn the ignition on, set the head unit volume low, and power the amp. Listen for a solid, deep thump. If you hear any clicking, buzzing, or a sudden loss of power, cut the power immediately and re‑inspect the bridge connections.

Once the sound is clean, tighten all mounting hardware, re‑install any panels you removed, and you’re ready to enjoy that extra horsepower in the low‑end frequencies.

That’s it – you’ve connected the speakers, set up the bridge, and turned a modest 4‑channel amp into a beefy mono‑bass engine. Next up we’ll talk about fine‑tuning the gain and protecting your system from over‑excursion.

Step 4: Adjust Gain and Test the System

Now that the bridge is solid, the next puzzle is getting the amp to deliver clean bass without turning your sub into a rattling speaker box. That’s where gain comes in – it’s the volume knob for the amp’s internal signal, not the head‑unit’s volume.

Why gain matters

If you crank the gain too high, the amp will clip the signal. You’ll hear that harsh “buzz‑buzz‑buzz” that makes any car‑audio enthusiast wince. Too low, and the sub will sound weak, never reaching its full punch. The sweet spot is right where the amp reproduces the input without distortion, letting the sub move the cabin.

Finding the sweet spot

Grab a simple 1 kΩ resistor or a 1 V test tone from a phone app. Set your head‑unit volume to about 75 % – that gives the amp enough headroom without maxing out the source.

- Turn the amp’s gain knob all the way down.

- Play a steady bass tone (around 50 Hz) and listen at the sub’s terminals with a multimeter set to AC volts.

- Increase the gain in small increments (about a quarter turn). Watch the voltage rise – you want roughly 0.7 × the amp’s rated RMS voltage.

- When the voltage plateaus or you start hearing distortion, back off a notch. That’s your gain setting.

For those who like a visual reference, the EEVblog forum thread discusses how to probe a bridged amp with an oscilloscope to spot clipping. It’s a handy read if you have an scope handy: EEVblog discussion on probing bridge amps.

Test the system safely

Before you hit the road, give the install a quick sanity check. Turn the ignition on, keep the head‑unit volume low, and power the amp.

Listen for a single, clean thump from the sub. No clicking, no rattling, no sudden silence. If anything sounds off, cut power immediately and re‑inspect the bridge connections and gain knob.

Next, run a short music track that hits the low end – a drum‑and‑bass song works well. Walk around the vehicle; you should feel a consistent push from the bass without any “popping” noises.

Finally, verify the amp’s protection circuits are engaged. Most modern amps have a built‑in thermal and over‑current shut‑off. Touch the amp’s heat sink after a few minutes of solid bass – it should be warm, not scorching. If it’s getting too hot, lower the gain a bit more or consider adding a small inline fuse as we mentioned earlier.

Once you’ve locked in that gain setting, tighten the knob lock (if your amp has one) and secure any loose wires with zip‑ties. Write down the knob position – a simple “3‑clicks from bottom” note saves you a lot of guesswork later.

That’s it. You’ve adjusted the gain, confirmed the signal is clean, and tested the whole system. With the bridge and gain dialed in, your sub will deliver that deep, controlled thump you were after. Ready to fine‑tune the crossover next? Stay tuned.

Step 5: Safety Checks and Troubleshooting

Alright, you’ve got the bridge wired and the gain set – now it’s time to make sure everything stays cool under pressure. A few quick safety checks can save you from a scorched amp or a dead sub later on.

Check the power feed

First thing’s first: verify that your power and ground wires are solid. Grab a multimeter, set it to continuity, and give the ground strap a quick beep test. No beep? Tighten that bolt or add a fresh ring terminal. A loose ground is the silent killer that makes amps overheat before you even notice.

Next, double‑check the fuse rating. If you followed the earlier advice and slipped a 2 A inline fuse for a 12‑AWG run, make sure the fuse isn’t blown right out of the box. A fresh fuse should read close to zero resistance; any sign of a high reading means a short somewhere in the harness.

Temperature sanity check

Run the amp for a couple of minutes at your usual listening level. While the bass thumps, gently touch the heat sink – it should feel warm, not scorching. If it’s hot enough to make you wince, back off the gain a notch or add a small vent to the enclosure. Most modern amps have thermal shut‑off, but you don’t want to rely on that as a safety net.

Pro tip: pop a temperature‑probe sticker on the amp’s case. It gives you a visual cue next time you walk under the dash.

Signal integrity test

Grab a 1 kΩ resistor and connect it between the sub’s terminals. Measure the AC voltage at the amp’s output while playing a steady 50 Hz tone. You should see a clean sine wave on an oscilloscope or a stable reading on a multimeter. Any wobble, clipping, or sudden drop indicates a wiring issue or a bad bridge connection.

If you don’t have an oscilloscope, listen for the classic “click‑click” when you tap the speaker terminals. A crisp click means the connection is solid; a muted or rattling sound suggests a loose screw.

Troubleshooting checklist

When something sounds off, walk through this quick list before you start pulling wires apart.

- Is the amp’s power fuse intact?

- Is the ground strap tight and free of paint or rust?

- Did you secure the bridge pins exactly as the manual says?

- Is the sub’s polarity correct? (+ to +, – to –)

- Are you running the amp within its rated bridged impedance?

- Did you leave the gain knob at the previously noted position?

If any answer is “no” or “maybe,” correct it and retest.

Common symptoms and fixes

Symptom: The sub cuts out after a few seconds.

Likely cause: Over‑current protection kicking in because the amp is seeing too low an impedance. Fix: Verify the sub’s impedance matches the amp’s bridged rating, or add a small series resistor to raise the load.

Symptom: You hear a high‑pitched whine when the car revs.

Likely cause: Ground loop or interference from the alternator.Fix: Add a 0.1 µF noise filter on the power leads, or re‑route the power cable away from the engine harness.

Symptom: The bass sounds thin or “wobbly.”

Likely cause: Polarity reversal or a loose speaker terminal.Fix: Flip the +/– wires on the sub, tighten the terminal screws, and re‑measure voltage.

Quick reference table

| Check | Tool Needed | What to Look For |

|---|---|---|

| Ground continuity | Multimeter (continuity mode) | Beep = solid ground; no beep = tighten or replace strap |

| Fuse integrity | Multimeter (resistance) | Near‑zero ohms = good; high resistance = replace fuse |

| Bridge voltage | Multimeter (AC volts) or oscilloscope | Stable ~0.7× amp RMS voltage; no clipping spikes |

By running through these safety steps, you’ll catch most issues before they turn your weekend project into a costly repair. And remember, a tidy install – zip‑ties, labeled wires, and a written gain note – makes troubleshooting a breeze the next time you tweak the sound.

So, does your system pass the safety checklist? If you’ve checked the power, ground, temperature, and signal, you’re ready to roll with confidence. Enjoy that deep, controlled thump, and feel free to come back for the final crossover tuning when you’re ready.

Conclusion

We've walked through every step of how to bridge a 4 channel amp, from mapping pins to tightening the final nuts. If you pause now, you can see the whole picture – a tidy diagram, the right wire gauge, polarity checked twice, and a safe gain setting.

So, what does that mean for you? It means you can squeeze extra power out of the amp you already own, without hunting for a brand‑new unit. That extra punch translates into deeper bass, louder road trips, and fewer headaches when the system finally sees the road.

Remember the three habits that keep the install reliable: label everything before you cut, verify continuity with a multimeter, and give the amp a brief power‑on test before you seal the panels. Those tiny habits are what separate a clean build from a future repair.

If you’ve followed the checklist, you’re ready to hit the highway and let that sub thump with confidence. Still have a question or need a second opinion? Our team at Audio Intensity is just a message away, happy to review your setup or point you toward the perfect bridge‑ready amp.

Now go ahead, fire up the bass, and enjoy the sound you’ve earned.

Happy listening, and stay tuned.

FAQ

Can I bridge any 4‑channel amp, or are there restrictions?

Not every 4‑channel amp can be bridged straight out of the box. Look for a bridge‑ready label in the manual or on the back panel – models like the ARC Audio MOTO 720 explicitly state a 2 Ω bridge mode. If the spec sheet only lists 4 Ω per channel, trying to bridge could force the amp into a load it wasn’t designed for, leading to overheating or shutdown. Always double‑check the manufacturer’s guidelines before you start wiring.

What wire gauge should I use when bridging a 4‑channel amp?

For most street‑legal builds 12‑AWG speaker cable is a solid choice. It handles the current a bridged pair can pull without adding too much resistance, and it’s easy to work with in tight dash spaces. If you’re pushing close to 400 W per bridge, stepping up to 10‑AWG gives you a little extra headroom and keeps the wires from heating under prolonged bass spikes.

How do I verify the amp’s bridge pins are correctly identified?

The safest way to confirm you’ve got the right pins is to use a multimeter in continuity mode. With the amp unplugged, place one probe on the positive terminal of the first channel and the other on the negative terminal of the second channel you intend to bridge. You should see a clean beep and a very low resistance reading, indicating the two outputs are isolated from the other pair. If you hear any resistance to the other channels, you’ve picked the wrong pins.

What impedance should I set for a bridged pair and why does it matter?

When you bridge two channels the amp sees half the load impedance, so a 4 Ω channel becomes a 2 Ω bridge. That matters because the amp’s current draw doubles, and not every model can handle the extra heat. Check the amp’s spec sheet: if it lists “2 Ω bridge” you’re good to go; if it only mentions 4 Ω, you’ll need to stick with a 4 Ω sub or add a small series resistor to raise the effective load. Matching impedance protects both the amp and your sub from premature failure.

Is there a safe way to test the bridge before I reinstall the panels?

Before you bolt the panels back, give the bridge a quick power‑on test with the head‑unit volume turned down low. Connect a short piece of 12‑AWG wire from the bridged outputs to a dummy 4‑Ω load or directly to the sub’s terminals, then listen for a single, clean thump. No clicking, no buzzing, and the voltage should sit steady around the expected RMS value. If anything sounds off, re‑measure the bridge voltage and double‑check polarity before you finalize the install.

What common mistakes cause the amp to overheat after bridging?

The most common cause of an amp overheating after you bridge is running a sub at a lower impedance than the amp’s bridge rating allows. That forces the amp to push more current than it’s built for, and the heat builds up fast. Another slip‑up is wiring the polarity backwards – the phase reversal makes the sub work harder and creates extra strain on the amp’s output transistors. Keep the gauge thick enough, respect the impedance spec, and always double‑check polarity before you power up.

Do I need to adjust the gain differently after bridging a 4‑channel amp?

After you’ve bridged the amp you’ll notice the gain knob now controls a much larger voltage swing, so the sweet spot shifts a few clicks forward. Start with the knob all the way down, play a steady bass tone, and raise the gain in quarter‑turn increments until the voltage at the sub’s terminals reaches about 70 % of the amp’s rated RMS voltage without any clipping. Write down the knob position – we usually note it as “3 clicks from bottom” – so you can return to the same setting later.