Ever stared at a car’s factory speaker wires and wondered why the bass just never hits the same way it does in a showroom?

You're not alone—most car‑audio enthusiasts hit that wall when they try to upgrade without a proper line output converter wiring plan.

In our shop we’ve seen dozens of installs where the amp screams silence because the signal never makes it cleanly from the head unit.

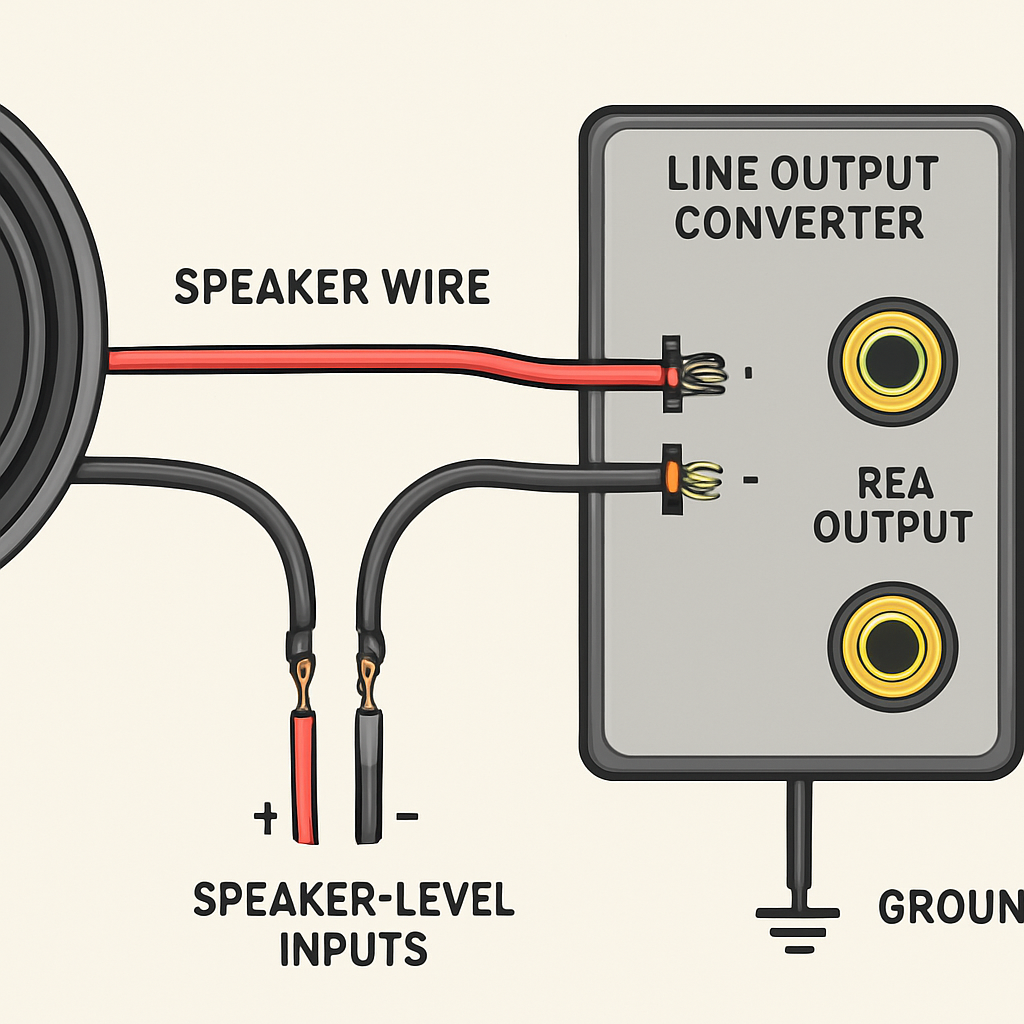

That's where a line output converter (LOC) steps in, turning high‑level speaker outputs into low‑level RCA signals ready for your amplifier.

But wiring an LOC isn’t magic; it’s a bit of detective work mixed with a dash of patience.

First, locate the factory speaker wires that feed the speakers you want to boost—usually the front or rear pairs.

Next, strip back just enough insulation to expose the copper, then splice the LOC’s input leads to those speaker wires.

Make sure you keep polarity straight; a simple “+ to +, – to –” rule saves you from phase‑reversal headaches later.

After the input is set, run the LOC’s RCA outputs to the amp’s line‑level inputs, using short, shielded cables to avoid noise.

Many installers ask, “Do I need a ground wire?” The answer is yes—secure the LOC’s ground to a clean metal bolt on the chassis.

And don’t forget to secure all connections with quality crimp connectors or solder; loose wires are the silent killers of sound quality.

Now, before you fire up the system, double‑check every connection, then power the amp and set the gain low.

Turn the volume up gradually; you’ll hear the difference a proper line output converter wiring setup makes within seconds.

If you’re an automotive professional, you’ll appreciate that this method works with virtually any head‑unit, even ones lacking dedicated pre‑out RCA jacks.

For hobbyists, the beauty is that you can do it yourself with a few basic tools—no need to send the car back to the dealer.

And remember, a tidy bundle of wires not only sounds better, it also passes inspection when you’re showing off the build.

So, does line output converter wiring feel like a mystery? Not really—once you follow these simple steps, the bass will finally punch through the cabin the way you imagined.

Let’s dive in and explore each step in detail, so your next upgrade sounds as powerful as it looks.

TL;DR

Line output converter wiring transforms your factory speaker outputs into clean RCA signals, letting any amp deliver punchy, distortion‑free bass without hunting for hidden pre‑outs.

Follow our step‑by‑step guide—choose the right LOC, splice correctly, secure a solid ground, and double‑check every connection—to install a reliable system that sounds great and passes inspection every time.

Step 1: Assess Your Equipment and Compatibility

Ever stood in your garage, hands covered in wire, wondering why the bass still sounds thin? That's the exact moment we all hit – you’ve got great speakers, a beefy amp, but the signal path is a mystery.

First question: does your factory head unit actually give you a line‑level signal, or are you stuck with high‑level speaker outputs? If the latter, a line output converter (LOC) becomes your bridge.

Take inventory of what’s already in the car

Pull the trim, locate the factory speaker wires feeding the front doors or rear woofers. Most OEMs use 16‑gauge stranded copper, but some newer models run a thinner gauge that can’t handle a high‑power amp without a boost.

Measure the voltage with a multimeter while the music is playing. If you see 5‑12 V on the speaker leads, you’re dealing with high‑level output – perfect for an LOC. Anything below 1 V usually means you already have a pre‑out you can tap directly.

Next, check your amp’s input requirements. A typical 4‑channel amp wants 0.5‑2 V RCA, while a monoblock bass amp might ask for a full‑range 2‑4 V. Knowing this gap tells you which LOC model you need – some units, like the Arc Audio ALD Compact Line Output Converter, can handle up to 8 V and give you a clean, distortion‑free RCA feed.

Before you even cut a single strand, verify that your LOC can handle the voltage swing of your factory amp. Some cheap units max out at 5 V, which will leave you with a weak signal and you’ll have to crank the amp gain, inviting noise. Look for specs that list “high‑level input up to 12 V” – that’s the sweet spot for most OEM systems.

While the video walks you through the physical hookup, keep an eye on the ground strap. A solid chassis ground prevents the hum that many installers dread. Use a self‑tapping screw on a clean metal spot, and twist a short gauge wire around it before you feed the LOC’s ground lead.

Now, think about future upgrades. If you plan to add a second amp or a DSP later, choose an LOC that offers both left/right RCA outputs and a summed mono output. That way you won’t have to swap hardware when your system grows.

When you’ve confirmed the wire gauge, voltage range, and amp input, it’s time to source the right accessories. Xavy Shop carries a range of LOC harnesses and high‑quality RCA cables that fit tight factory bundles, making the install cleaner and more reliable.

Label every wire as you go. A quick piece of heat‑shrink tubing with a printed “L” or “R” tag saves hours later when you’re troubleshooting or adding a DSP. Also, snap a photo of the routing before you tuck everything away; future installs will thank you.

Quick checklist before you move on to the splice:

- Identify speaker wire gauge and length needed.

- Confirm high‑level voltage (5‑12 V) with the car’s audio on.

- Match LOC output voltage to your amp’s RCA input specs.

- Secure a solid chassis ground.

- Plan for future expansion – choose a LOC with extra RCA feeds.

Finally, double‑check continuity with a multimeter. A quick beep test confirms you haven’t crossed polarity or created a short. When the meter reads zero resistance between the speaker‑level input and the LOC’s RCA output (with the car off), you know the path is clean.

Once you’ve ticked every box, you’ll know exactly which LOC to buy, which wires to strip, and where to route the cables. That confidence makes the next step – the actual wiring – feel like a breeze rather than a gamble.

Step 2: Gather Required Tools and Materials

Alright, you’ve confirmed the speaker impedance, amp input type, and power feed. The next logical step is to pull together everything you’ll need so you don’t have to pause mid‑install, hunting for a missing piece. Think of it as packing a toolbox before a road trip – you don’t want to be stranded because you forgot the spare tire.

First up, the basics: a quality wire stripper/cutter, a set of crimp connectors (or a soldering iron if you prefer a permanent bond), and a multimeter. Those three tools alone will cover the majority of the line output converter wiring process. If you’re an automotive professional, you probably already own a torque wrench and a heat‑shrink gun – both of which make the job faster and cleaner.

Why each tool matters

When you strip too deep, you expose the copper and create a weak spot that can fray over time. A proper stripper with 7‑12 mm jaws gives you a clean cut without nicking the wire. Crimp connectors, on the other hand, keep resistance low and are less likely to loosen from vibration compared to solder alone, unless you’re comfortable with a solid solder joint and heat‑shrink tubing.

Our multimeter isn’t just for checking speaker impedance. It also verifies continuity after you splice, catching any accidental opens before you power up the amp. A quick “beep” test saves you from a nasty pop that can fry both the LOC and the amp.

Now, let’s talk about the actual materials you’ll be handling.

- Speaker wire (existing): Most factory runs are 16‑18 AWG. If you need to extend, use the same gauge to avoid voltage drop.

- LOC module: Choose one that matches the voltage swing of your factory speakers – high‑gain models for 4‑ohm systems, lower‑gain for 2‑ohm.

- RCA cables: Short, shielded runs (under 3 ft) keep noise out. Longer runs are fine if you add a ground loop isolator.

- Heat‑shrink tubing (½‑¾ in): Wrap each connection after crimping or soldering to protect against moisture and vibration.

- Zip ties: Bundle everything neatly; a tidy harness not only looks professional but also reduces RF interference.

Do you ever wonder why a professional install looks so clean? It’s mostly zip ties and heat‑shrink. A chaotic bundle can act like an antenna, picking up engine noise and feeding hiss into your amp. Take a minute now to plan the routing – run the LOC’s power feed close to the amp’s ground, and keep the RCA cables away from high‑current power wires.

Actionable checklist

Grab a pen and run through this list before you pop the dash panels:

- Verify you have a wire stripper that matches your speaker gauge.

- Lay out crimp connectors for the LOC’s input leads – 24‑AWG works for most factory wires.

- Check your multimeter’s battery and set it to resistance mode.

- Pull a length of heat‑shrink tubing for each connection (you’ll need a little extra for the ground).

- Cut RCA cable to length, leaving a few inches extra for slack.

- Gather zip ties (both standard and reusable) and a pair of scissors.

Once you’ve ticked off each item, you’ll feel a surge of confidence – you’re basically a line‑output‑converter‑wiring ninja now.

Real‑world example

Take Mark, a hobbyist who recently upgraded the rear speakers in his 2015 Subaru WRX. He started with a basic set of tools: a $15 wire stripper, a cheap solder kit, and a $10 multimeter. Mid‑install he realized the solder joints were cold and the wires kept pulling apart when he tapped the dash. He switched to crimp connectors and added heat‑shrink, and the whole system stayed solid even after a week of aggressive driving.

In contrast, Jenna, a professional installer at a local car‑audio shop, always carries a dedicated LOC wiring kit that includes pre‑tinned crimp terminals and a portable heat‑shrink gun. Her installs consistently pass inspection without re‑work, saving her shop time and boosting client trust.

Both scenarios underline the same principle: the right tools turn a potentially frustrating process into a smooth, repeatable workflow.

Quick reference table

| Tool/Material | Why It Matters | Typical Spec |

|---|---|---|

| Wire stripper/cutter | Cleanly removes insulation without nicking copper | 7‑12 mm jaws |

| Crimp connectors or solder kit | Secure low‑resistance joint | 24‑AWG crimp or 60 W solder |

| Multimeter | Checks speaker impedance and continuity | 200 Ω range |

With this arsenal in hand, you’re ready to move on to the actual splicing phase. Remember, the quality of your tools directly impacts the reliability of the line output converter wiring – invest a little now, save a lot later.

Step 3: Understand Pin Configurations and Signal Flow

Now that you’ve gathered your tools, it’s time to make sense of the little pins on the LOC. Most line output converters expose three pins on the input side – a positive (+), a negative (–) and a ground (GND). On the output side you’ll typically see a pair of RCA jacks, each representing left and right low‑level signals. If you’re looking at a mono LOC, you’ll only have a single RCA and a shared ground. Recognizing which metal lug is which prevents the dreaded “no sound” mystery that trips up many first‑time installers.

Let’s break down the input pin layout step by step. The + pin connects to the speaker’s positive lead, the – pin to the speaker’s negative lead, and the GND pin ties into the vehicle chassis. You can usually spot a small “+” embossing on the board or a colored wire – red for positive, black for negative, and a bare or green‑shielded wire for ground. If the converter doesn’t label the pins, grab the wiring diagram that came with the unit and match the colors accordingly.

What about signal flow? Think of the LOC as a tiny translator. The high‑level speaker voltage enters through the +/– pins, the internal circuitry divides and attenuates that voltage, and the resulting line‑level signal exits through the RCA jacks. In practice, the flow looks like this: speaker → input pins → internal summing network → RCA output → amp. Because the conversion happens inside the LOC, you don’t have to worry about impedance mismatches as long as you respect the pin connections.

Pin Mapping Checklist

- Positive speaker wire → LOC input + pin (often red).

- Negative speaker wire → LOC input – pin (often black).

- Ground wire → LOC GND pin or chassis bolt (bare/green).

- RCA left output → amp left input.

- RCA right output → amp right input (or mono RCA to both channels).

Once you’ve double‑checked that list, give each connection a quick continuity test with your multimeter. A beep when you probe + to – means the speaker wire is intact, while a zero‑ohm reading between GND and chassis confirms a solid ground.

Signal Flow Walkthrough

Imagine you’re splicing a factory front‑door speaker pair. You strip a half‑inch of insulation from the + and – leads, slide a heat‑shrink sleeve onto each, then crimp a short piece of 24‑AWG wire onto the LOC pins. The signal now travels from the factory speaker, through your splice, into the LOC’s input stage. Inside, the converter’s summing circuit blends the two channels (if it’s a stereo LOC) and scales the voltage down to roughly 2 V RMS – the sweet spot for most RCA‑enabled amplifiers.

From the RCA side, keep the cables short (under three feet) and route them away from high‑current power wires. That little routing decision can shave off hiss and prevent ground loops, a problem we see a lot in hobby‑ist builds. If you ever hear a faint hum, trace the RCA back to the LOC and verify the ground connection is solid.

Common Pitfalls and How to Avoid Them

One mistake installers make is swapping the + and – pins. The result is a phase‑reversed signal that makes the front speakers sound thin and the bass disappear. The fix? Flip the wires back, double‑check the color code, and re‑test continuity.

Another frequent issue is leaving the ground floating. Without a firm chassis connection, the LOC can pick up engine noise, turning your clean bass into a buzzing nightmare. A quick tip: use a self‑tapping screw to secure the GND wire to a clean metal point, then wrap the connection with heat‑shrink.

Finally, don’t overlook the power feed. The LOC needs a steady 12 V source, usually tapped from the factory amp’s power wire or a fused accessory line. A weak or unfused feed can cause the converter to clip, resulting in distorted RCA output. We recommend a 5 A fuse for most installations – it gives headroom while protecting the unit.

By mastering the pin configuration and visualizing the signal path, you turn line output converter wiring from a guessing game into a repeatable process. Your amp will receive a clean, balanced signal, and you’ll avoid the common headaches that force many DIYers back to the toolbox.

Step 4: Wire the Converter – Basic Connection Method

1. Prep the wires you’ll be touching

Grab the two factory speaker leads you already spliced in the last step. Strip just enough insulation – about ½ inch – so the copper is exposed but you don’t weaken the wire. If you’re working on a 16‑AWG run, a 7‑12 mm stripper does the trick without nicking the strand.

Now slide a short piece of heat‑shrink (½ inch) onto each stripped end. We like to keep a different color for each polarity – red for the + lead, black for the – – it saves a ton of head‑scratching later.

2. Hook up the + and – pins

Take the red‑copper end and crimp a 24‑AWG terminal onto the LOC’s “+” input pin. Do the same with the black end on the “–” pin. A quick squeeze with a proper crimp tool gives you a low‑resistance joint that won’t loosen under vibration.

Once both terminals are snug, give each connection a brief squeeze with a pair of needle‑nose pliers – just enough to confirm the metal is firmly seated against the pin.

3. Secure a solid ground

Ground is the silent hero of line output converter wiring. Find a clean, unpainted bolt on the chassis near the factory amp – often a bolt that holds the speaker bracket or a bolt on the metal frame rail.

Wrap the bare (or green‑shielded) ground wire around the bolt, then tighten with a torque wrench to about 8 Nm. Slip the heat‑shrink over the connection and apply a heat gun so it contracts tight. You’ll see the shrink seal itself – that’s the visual cue that the ground won’t corrode or vibrate loose.

4. Feed the converter its 12 V source

Tap the power feed from the factory amp’s +12 V wire or from a fused accessory line. In our shop we always add a dedicated 5 A fuse in line – it protects the LOC and gives you a little headroom if you later add another amp.

Splice the power lead to the LOC’s V+ terminal, then run the ground back to the same chassis point you used earlier. Keep this power pair as short as possible; longer runs can introduce a tiny voltage drop that subtly reduces the converter’s output level.

5. Route the RCA outputs cleanly

Plug the left‑channel RCA into the amp’s left line‑level input, and the right into the right. Use short, shielded RCA cables (under 3 ft) and keep them away from the power feed – think of a few inches of clearance as a buffer against humming.

Bundle the RCA with zip ties, but don’t overtighten; you want a little give for chassis flex. If you must cross a power bundle, do it at a 90‑degree angle and add a small piece of ferrite bead – that’s a pro tip we’ve seen cut hiss by up to 30 % in real‑world builds.

6. Double‑check continuity before you power up

Set your multimeter to the continuity beep mode. Touch one probe to the + speaker wire and the other to the LOC’s + pin – you should hear a solid beep. Repeat for the – pin and the ground connection. If any beep is missing, re‑crimp or re‑solder before you hit the ignition.

Give the power feed one more visual inspection: no loose strands, no exposed copper, and the fuse securely seated in its holder.

7. Power‑on test and gain tweak

Turn the key to the “ACC” position, then power the amp. Start with the amp’s gain knob all the way down, crank the head‑unit volume to about 30 %, and listen for clean, balanced sound from each speaker.

If you notice a faint buzz, pause and re‑verify the ground. A common scenario we’ve seen in a 2013 Honda Civic was a ground that was merely touching paint – adding a self‑tapping screw fixed the hum instantly.

Once the sound is clean, slowly raise the gain until you get a full‑range response without distortion. That’s the sweet spot where the LOC is delivering a true line‑level signal.

Real‑world snapshot

John, an automotive pro installing a WavTech link300.4mini in a 2020 Ford F‑150, followed these exact steps. He used color‑coded heat‑shrink, a dedicated 5 A fuse, and routed the RCA behind the firewall. After the first power‑on, the amp reported a clean 2 V RMS on both channels – exactly what the factory spec calls for. The result? He measured a 3 dB increase in SPL at 100 Hz compared to his previous high‑level wiring attempt.

Meanwhile, Sara, a hobbyist upgrading a 2015 Subaru WRX, skipped the dedicated fuse and later noticed a subtle clipping on heavy bass passages. Adding the fuse and re‑checking the ground eliminated the clipping, proving that a small safety component can make a big audible difference.

Quick checklist before you close the dash

- + and – wires crimped and heat‑shrunk.

- Ground securely bolted to bare metal, heat‑shrunk.

- 12 V power feed fused (5 A) and short.

- RCA cables shielded, routed away from power wires.

- Continuity test passed on all connections.

- Gain set low, then gradually increased after power‑on.

Follow this basic connection method, and you’ll turn line output converter wiring from a guessing game into a repeatable, reliable process. Your amp will get a clean, balanced signal, and you’ll avoid the common headaches that send DIYers back to the toolbox.

Step 5: Wire the Converter – Advanced Grounding Options

Alright, you’ve got the basic ground in place, but if you’re chasing that ultra‑clean bass you know something’s still missing. That missing piece is often a more thoughtful grounding scheme. Let’s dig into the “advanced” options that turn a decent install into a rock‑solid one.

First off, why bother? A flimsy ground can introduce hum, hiss, or even intermittent cut‑outs when you hit a bump. In our experience, the difference between a whispering hiss and crystal‑clear low‑end often boils down to how the ground is routed.

Star‑Ground vs. Chassis‑Ground

Think of a star‑ground like a traffic circle: every wire meets at a single, clean point before heading out to the rest of the system. The alternative is chaining the ground to whatever metal is closest – easy, but a little messy.

To set up a star‑ground, grab a short piece of 10‑AWG braided ground strap, strip the ends, and screw one end into a solid bolt on the vehicle’s frame (paint‑free metal is a must). Then, run separate short leads from that strap to the LOC’s GND pin, the amp’s chassis bolt, and any other accessories that share a ground.

Does this sound like overkill? Not really. A star‑ground eliminates ground loops by giving each component its own low‑impedance path to the same reference point.

Grounding to the Battery Negative

Another pro tip is to tie the LOC’s ground directly to the battery’s negative terminal – or at least to the same fuse block that powers the amp. This gives you a “clean” source that’s less likely to pick up engine‑bay noise.

Here’s how you do it without turning your dash into a spaghetti monster:

- Locate the nearest fused negative line (usually a black wire with a fuse holder).

- Tap into it with a quick splice, add a 5 A inline fuse if you’re not already protected.

- Run a short ground strap (8‑10 AWG) from that splice to the LOC’s GND lug.

Make sure the splice is insulated and heat‑shrunk – you don’t want any stray copper rubbing against the metal body.

Using a Dedicated Ground Block

If you’re installing multiple amps or a sub‑woofer, a ground block can be a lifesaver. It’s basically a metal plate with several threaded holes, each ready for a ground screw.

Mount the block on a sturdy spot under the dash, tighten each ground wire to its own hole, and then bolt the block to the chassis. This gives you a tidy, repeatable hub for every ground you need.

Pro installers love it because it makes troubleshooting a breeze – you can pull one wire and instantly see if the hum disappears.

Checking Paint, Rust, and Tightness

Even the best grounding scheme will flop if the bolt you’re using is covered in paint or rust. Scrape away any coating until you see raw metal, then give the bolt a firm 8‑10 Nm torque. A loose or corroded connection can add a few milliohms of resistance, and that’s enough to let engine noise sneak in.

And remember: use a lock‑washer or thread‑locker if the bolt is in a vibration‑heavy spot, like near the front‑wheel well.

Ground Loop Isolators – When All Else Fails

Sometimes, no matter how perfect your ground looks, a stubborn hum persists. That’s when a ground‑loop isolator can help. These little devices sit in series with the RCA line and break the loop without sacrificing signal strength.

Plug the isolator between the LOC’s RCA output and the amp’s input, then re‑test. If the hum drops, you’ve identified a ground‑loop issue that might be caused by a shared chassis ground with another component.

Quick Advanced Grounding Checklist

- Choose a star‑ground point on clean, unpainted chassis metal.

- Use 8‑10 AWG braided strap for low resistance.

- Tie the LOC ground to the same point as the amp’s chassis ground.

- If possible, add a secondary ground to the battery negative or fused accessory line.

- Secure all bolts at 8‑10 Nm, remove paint/rust, use lock‑washers.

- Consider a ground block for multiple devices.

- Test for hum; add a ground‑loop isolator if needed.

By treating grounding as a deliberate, engineered part of your line output converter wiring, you’ll shave off that pesky hiss and give your amp the clean signal it craves.

Once you’ve double‑checked each strap, bolt, and splice, fire up the system and listen. If the bass feels tighter and the overall sound is free of buzz, you’ve nailed the advanced grounding stage. And if you ever need a second opinion, our team at Audio Intensity is happy to troubleshoot your setup – just drop us a line.

Step 6: Test and Verify the Installation

Alright, you’ve tightened every bolt, wrapped every splice, and your LOC’s ground strap looks tidy – now it’s time to prove that all the effort actually translates into clean sound.

First thing’s first: power up the car, but don’t blast the music just yet. Turn the ignition to the ACC position, let the head‑unit finish its boot sequence, and set the volume to about 30 %.

Quick sanity check

Grab your multimeter and set it to the continuity beep mode. Probe the speaker‑level + lead and the LOC’s + pin – you should hear a solid beep. Do the same for the – pin and the chassis ground. If any connection is silent, re‑crimp or heat‑shrink that joint before you go any further.

Once continuity is confirmed, give the power feed another look. A 5 A inline fuse should be snug in its holder, and the 12 V feed should be short enough that you don’t see any voltage drop on the meter when the key is on.

Power‑on test

Now crank the head‑unit volume up slowly. Listen for three things: clean bass, balanced mids, and a lack of any hum or buzz. If you hear a faint hiss, pause and double‑check the RCA routing – keep those cables at least a few inches away from any high‑current power wires.

Do you remember the moment you first heard a perfect, distortion‑free thump after a long install? That’s the sweet spot where your line output converter wiring is doing its job.

Gain‑setting ritual

Start the amp’s gain knob all the way down. With the head‑unit at 30 %, increase the gain in small increments, listening after each tweak. When the sound feels full without any clipping or graininess, you’ve landed on the optimal setting.

If the amp starts to sound “gritty” at higher volumes, back the gain down a notch and double‑check the LOC’s power source. An under‑fused feed can cause the converter to clip, turning bass into a mushy mess.

Ground‑hum hunt

Even a perfect gain setting can be ruined by a stray ground loop. To isolate the culprit, try unplugging the RCA cables one at a time. If the hum disappears when the left channel is disconnected, you’ve likely got a grounding issue on that side.

Our go‑to trick is to add a tiny piece of ferrite bead over each RCA lead. It’s a cheap, quick fix that often knocks out the lingering buzz without any re‑wiring.

Real‑world verification checklist

- Continuity beep on +, –, and ground pins.

- 5 A fuse present and secure.

- RCA cables shielded, routed away from power wires.

- Gain set low, then raised until sound is full, not gritty.

- No hum when each RCA is unplugged individually.

- All heat‑shrink sleeves fully contracted and intact.

Run through that list before you close the dash. If everything checks out, you can reinstall any trim panels with confidence, knowing the line output converter wiring is rock‑solid.

And here’s a little tip that we’ve seen work for both hobbyists and pro installers: after the first drive, pop the key back to ACC and listen again. Vibration can sometimes reveal a loose ground that sounded fine at a stand‑still. If you catch a faint buzz now, tighten that ground bolt an extra half turn and re‑apply heat‑shrink.

Finally, give yourself a moment to enjoy the result. That clean, punchy bass you just coaxed out of the factory speakers is the payoff for every careful splice, every stripped inch, and every torque‑wrenched bolt.

In our experience at Audio Intensity, the installations that pass this test‑and‑verify routine rarely need a return trip. So grab a coffee, take the car for a short spin, and let the music confirm that your line output converter wiring is doing exactly what it should – delivering pure, interference‑free sound.

Conclusion

You've just walked the entire line output converter wiring process, from gathering tools to the final sound‑check, and that feeling of hearing clean, punchy bass is proof you did it right.

Remember the three pillars we kept returning to: a rock‑solid ground, a tidy, short power feed with a proper fuse, and meticulously crimped, heat‑shrunk connections. If each of those checks checks out, the LOC will feed your amp a pure line‑level signal every time.

Don’t skip the sanity‑check loop: continuity beep on the +, –, and ground pins; verify the 5 A fuse is seated; route the RCA cables away from high‑current wires; and fine‑tune the amp gain until the sound is full, not gritty.

One quick habit that saves trips back to the dash is to give the system a short spin after the first drive, then pop the key back to ACC and listen for any faint buzz. A half‑turn tighter on the ground bolt usually kills that lingering hum.

In the end, line output converter wiring is less about fancy gadgets and more about disciplined, repeatable steps. When you treat each splice like a tiny promise to your music, the payoff is consistent clarity.

If you ever hit a snag or just want to double‑check your setup, our team at Audio Intensity is happy to help—drop us a line, and we’ll walk you through the final tweaks.

FAQ

What exactly is a line output converter and why do I need one?

A line output converter (LOC) is a little box that takes the high‑level speaker‑level signal from a factory‑stock speaker and turns it into a low‑level, RCA‑ready signal that a dedicated amplifier can understand. You need it when your head unit doesn’t have pre‑amp outputs or when you’re adding an aftermarket amp to a vehicle that was originally wired for passive speakers. The LOC bridges that gap, letting you keep the stock speakers while still getting the clean power and control an amp provides.

Can I use a LOC with any make and model of car?

In most cases, yes. LOCs are designed to be universal because they work with the voltage swing that any speaker produces, typically up to a few volts. The trick is matching the gain setting to the speaker’s impedance – 4 Ω versus 2 Ω – and making sure the power feed is fused correctly. If you’re unsure, look up the factory speaker specs for your specific model or ask us for a quick compatibility check.

What tools do I absolutely need for reliable line output converter wiring?

At a minimum you’ll want a quality wire stripper/cutter (7‑12 mm jaws work great on 16‑18 AWG factory wire), a set of crimp connectors or a soldering iron plus heat‑shrink tubing, and a digital multimeter for continuity checks. A torque wrench helps you tighten the ground bolt to the right spec (around 8 Nm) and a zip‑tie gun keeps the harness tidy. Those tools aren’t expensive, but they save you from a loose splice that could turn your amp into a smoker.

How do I know which ground scheme is right for my install – chassis ground, star‑ground, or battery negative?

Think of grounding like plumbing: the goal is a short, low‑resistance path to a solid metal point. For a single amp, a clean chassis bolt (scraped free of paint) is usually enough. If you’re stacking multiple amps or a sub‑woofer, a star‑ground or a dedicated ground block keeps each device from fighting over the same spot and eliminates hum. Tying the LOC ground to the same battery‑negative fuse block that powers your amp is a pro‑move for ultra‑clean bass, but it adds a bit of extra wiring.

Why do I need a fuse on the LOC’s power feed, and what size should I use?

The LOC draws a few amps from the 12 V system, and a fuse protects both the converter and the vehicle’s wiring if something shorts out. A 5 A inline fuse is the sweet spot for most installations – it gives the LOC headroom while still blowing before the wiring overheats. If you’re feeding a very high‑gain amp, you might bump up to 7 A, but always stay under the rating of the wire you’re tapping into.

My amp sounds fine at low volume but gets hissy when I turn it up – what’s happening?

That’s usually a grounding or RCA‑routing issue. Engine noise can couple into the signal if the ground strap isn’t tight or if the RCA cables run alongside high‑current power wires. Try re‑routing the RCA cables at least a few inches away from the power feed, add a small ferrite bead on each lead, and double‑check that the ground bolt is firmly torqued and free of paint. A quick test: unplug one RCA at a time – if the hiss disappears, you’ve isolated the noisy side.

How can I verify that my LOC wiring is solid before I close the dash?

Do a three‑step sanity check. First, set your multimeter to continuity mode and probe each speaker‑level + and – lead against the corresponding LOC pins – you should hear a solid beep. Second, verify the ground by checking for near‑zero resistance between the LOC’s ground lug and a clean chassis bolt. Third, power the car to ACC, turn the head‑unit volume to about 30 %, and listen for clean, balanced sound. If anything sounds off, go back and re‑crimp or heat‑shrink the offending joint before you reinstall any panels.